Procedure

Dive into LightWaste's eco-friendly candle-making process: crafting from various organic bases, rigorous testing, and strategic marketing. Aligned with three Sustainable Development Goals, our journey is fueled by partnerships with ISEP and Castelbel.

Click on each title for more informations.

LightWaste emerged from our pursuit of issues close to our hearts and our commitment to finding innovative, eco-friendly solutions to minimize them. Our journey unfolded as we transitioned to studying what is called the Green Market, by exploring lab procedures and sustainable materials, as well as fostering potential partnerships.

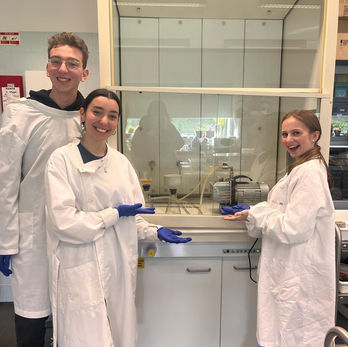

We source materials for both our candle-making endeavors and comprehensive marketing studies. Collaborative partnerships with ISEP and Castelbel contribute valuable resources, complemented by the materials available within our school and homes.

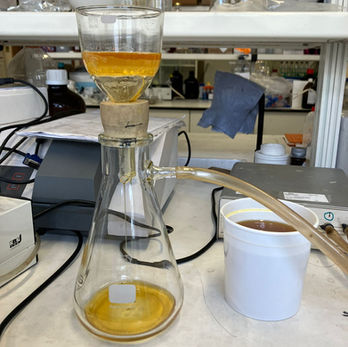

The wax results from vacuum filtration, a brine wash, and purification with almond husks of the oil. The colour and fragrance are obtained by adding filtered oil from ground fruit peel. For the final consistency, the solution is hydrogenated.

In our quest for the perfect eco-friendly candle, we'll be conducting trials with varying concentrations of oils and juice extracted from vegetable and fruit peels before solifying the wax. These experiments aim to address challenges like flame and burn duration, decomposition, unusual colors, and smells, ultimately leading us to our final product.

Once we've perfected our first and best candle, this section will showcase the right protocol, providing insights into the journey and discoveries that shaped our sustainable creation.

With the success of our initial sample, we will then be set to replicate the process and craft diverse candle variations that resonate with public taste. Guided by insights from an ongoing market study, we aim to align our product offerings with the preferences of our audience.

As our first line nears completion for its grand debut, our focus will shift to creating beautiful designs for the candle holders and packaging. Simultaneously, our website and social accounts are undergoing enhancements, gearing up to effectively promote our eco-friendly products.

Finally ready, we will embark on our journey to promote and sell our products. The first LightWaste candle entering a consumer's home becomes a symbolic milestone. Forever guided by our slogan, 'We burn the waste to light up your future' each flicker represents our commitment to illuminating a greener, more sustainable path forward.

Anticipating Challenges

Here we present comprehensive solutions, reflecting our commitment to transparency and the continuous pursuit of sustainable practices.

-

Addressing the potential limitation of flame duration and burn difficulty, we will have implemented a specialized filtration and hydrogenation procedure, only possible with the engeneer college chemistry department's help, applied to used cooking oil. This process ensures a wax composition similar to existing candles, while retaining the distinct color and fragrance derived from oranges.

-

Addressing concerns related to unexpected smells from used cooking oil and the potential decomposition of organic materials, we have devised a solution. By employing thoroughly tested combinations of fragrances derived from commonly appreciated natural aromatic plants, we are going to carefully select a minimal quantity of those that decompose faster while maintaining an appealing scent.